Overview

Dry-type iron-core series reactors are used in low-voltage reactive power compensation panels and are connected in series with capacitors. When a low-voltage power grid contains numerous harmonic sources, such as rectifiers and converters, the high-order harmonics they generate can seriously endanger the safe operation of the main transformer and other electrical equipment. When connected in series with capacitors, these reactors effectively absorb grid harmonics, improve the system voltage waveform, and enhance the system power factor. They also effectively suppress closing inrush current and switching overvoltage, effectively protecting the capacitors.

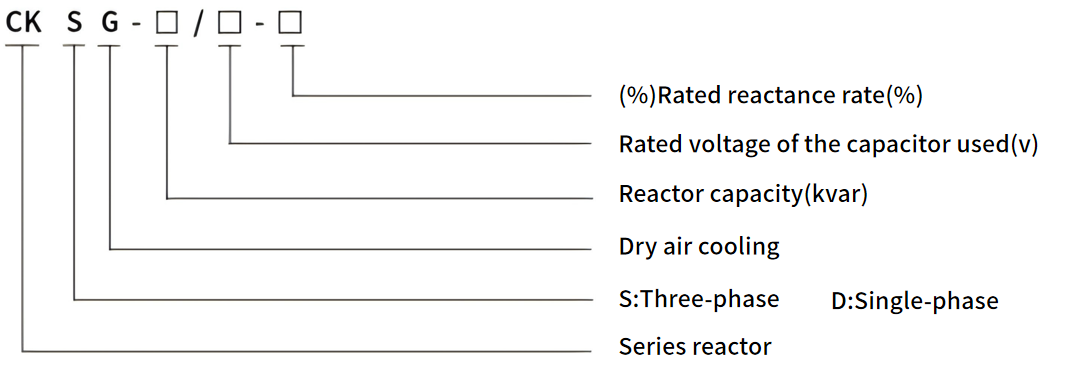

Models and Meanings

Structural characteristics

1. This reactor is available in three-phase and single-phase versions, both featuring dry-type iron cores.

2. The core is constructed from high-quality, low-loss imported cold-rolled grain-oriented silicon steel sheets. The core legs are divided into uniform segments by multiple air gaps, separated by epoxy-laminated glass cloth sheets to ensure that the air gaps remain constant during operation.

3. The coils are wound with F-class enameled rectangular copper wire, tightly and evenly arranged without an insulating layer, resulting in an aesthetically pleasing design and excellent heat dissipation.

4. After the coils and core are assembled, they undergo a process of pre-baking, vacuum impregnation, and thermal curing. Using H-class impregnation varnish, the coils and core are firmly bonded together, significantly reducing operational noise and providing an extremely high heat resistance rating, ensuring safe and quiet operation even at high temperatures.

5. The fasteners in the reactor legs are made of non-magnetic material, ensuring a high quality factor and low temperature rise, ensuring excellent filtering performance. 6. All exposed parts are treated with corrosion protection, and the lead terminals utilize cold-pressed copper tube terminals.

7. Compared to similar domestic products, this reactor boasts advantages such as smaller size, lighter weight, and more attractive appearance, rivaling well-known international brands.

Conditions and parameters of use

1. Altitude not exceeding 1000 meters.

2. Operating ambient temperature -25°C to +45°C, relative humidity not exceeding 90%.

3. No hazardous gases or flammable or explosive materials are present in the surrounding area.

4. The surrounding environment must have good ventilation. If installed in a cabinet, ventilation equipment should be installed.

Technical Parameters

1. Applicable to 400V and 660V systems.

2. Reactance rating options: 1%, 6%, 7%, 12%, 13%, and 14%.

3. Rated insulation level: 3kV/min.

4. Temperature rise limits for all parts of the reactor: Core temperature not exceeding 85K, coil temperature not exceeding 95K.

5. Reactor noise level not exceeding 45dB.

6. The reactor can operate for long periods at power frequency plus harmonic currents not exceeding 1.35 times the rated current.

7. Reactance linearity: The ratio of the reactance value at 1.8 times the rated current to the reactance value at the rated current must be no less than 0.95.

8. The difference in reactance between any two phases of a three-phase reactor must not exceed ±3%.

9. Temperature resistance grade: HF grade (180℃) or above.

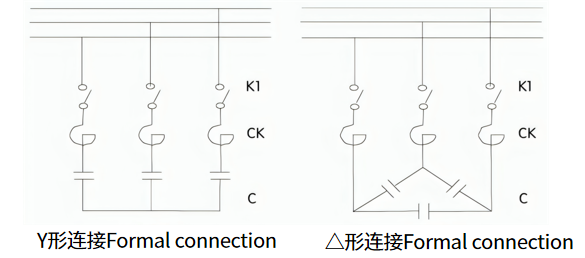

Wiring method

Installation dimensions

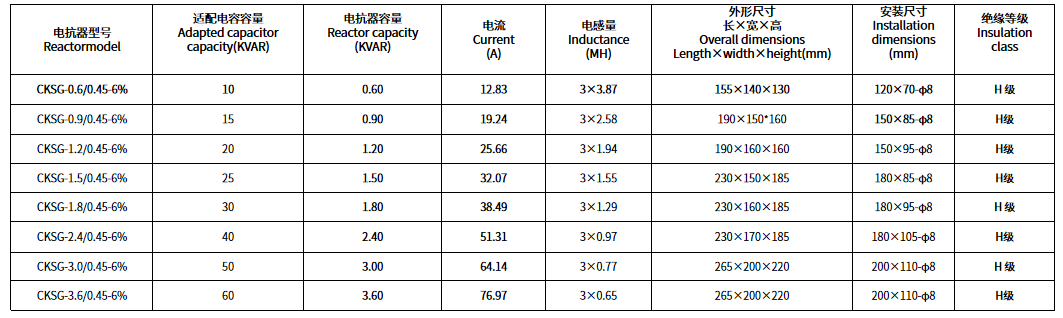

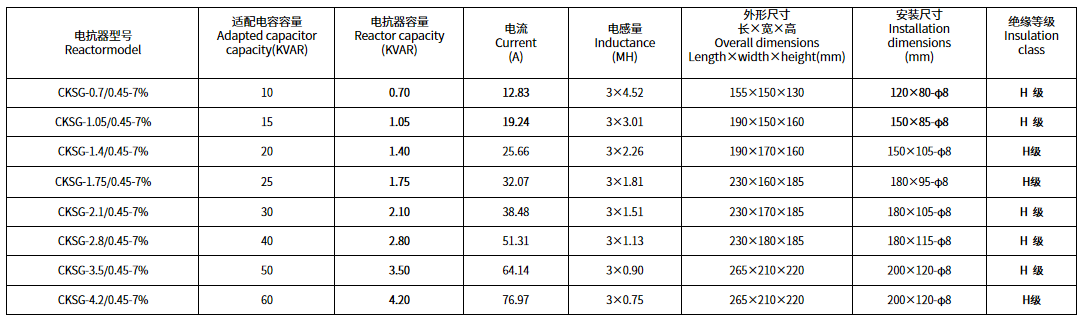

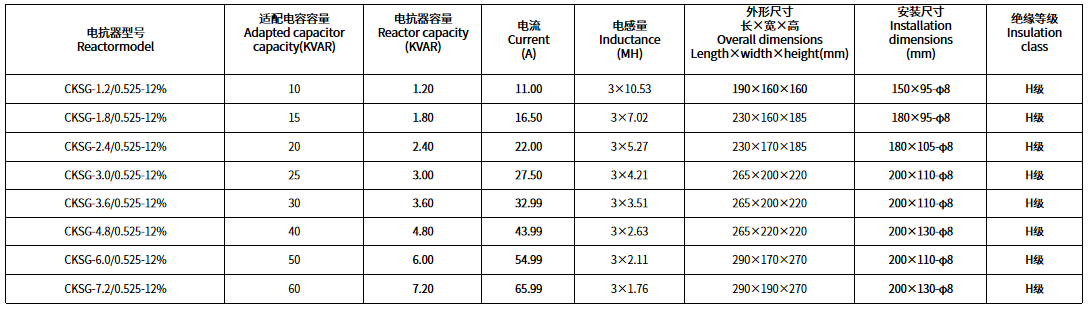

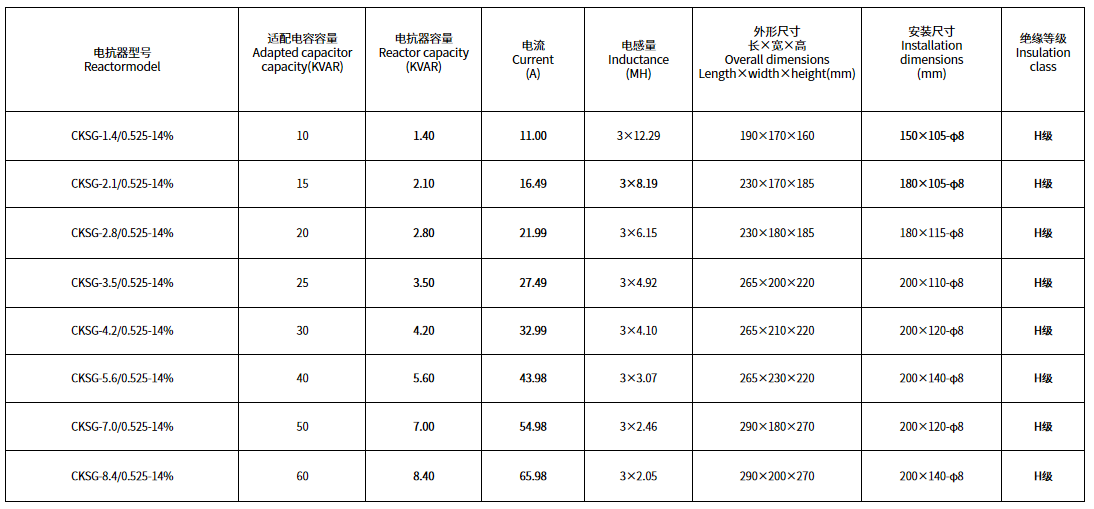

Specifications and model parameters

Note: The above specifications are commonly used and are for reference only. Reactors with other voltage levels, capacities, and reactance ratings can be manufactured upon request. We reserve the right to modify these specifications.